Product Details

Size : 1/2"NB TO 60"NB IN

Pressure: Class 75, Class 150, Class 300, Class 400, Class 600, Class 900

Standard: ANSI B16.47, ASME B16.47

Type: Welding Neck Flanges

Process: Forged and Stamped

Coating: Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

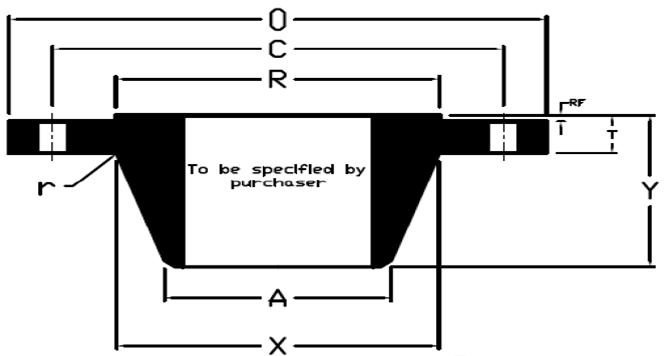

Dimension:

ANSI/ASME B16.5, ANSI/ASME B16.47 Series A (MSS SP-44), ANSI/ASME B16.47 Series B (API 605),

ANSI/ASME B16.36, ANSI/ASME B16.48 (API 590)

ASME B16.47 Class 150 Series B Welding Neck Flanges | ||||||||||||

Nominal Pipe Size | Outside Diameter (O) | Maximum Thickness (T) | Raised Face Diameter (R) | Length Thru Hub (Y) | Hub Diameter (X) | Minimum Fillet Radius (r) | Top of Hub (A) | Bore (B) | Approximate Weight (lbs) | Bolt Circle (C) | Number of Holes | Diameter of Holes |

26 | 30.94 | 1.62 | 28 | 3.5 | 26.94 | 0.38 | 26.06 | Specified by | 120 | 29.31 | 36 | 0.88 |

28 | 32.94 | 1.75 | 30 | 3.75 | 28.94 | 0.38 | 28.06 | Specified by | 140 | 31.31 | 40 | 0.88 |

30 | 34.94 | 1.75 | 32 | 3.94 | 31 | 0.38 | 30.06 | Specified by | 150 | 33.31 | 44 | 0.88 |

32 | 37.06 | 1.81 | 34 | 4.25 | 33.06 | 0.38 | 32.06 | Specified by | 170 | 35.44 | 48 | 0.88 |

34 | 39.56 | 1.94 | 36.25 | 4.34 | 35.12 | 0.38 | 34.06 | Specified by | 210 | 37.69 | 40 | 1 |

36 | 41.62 | 2.06 | 38.25 | 4.62 | 37.19 | 0.38 | 36.06 | Specified by | 240 | 39.75 | 44 | 1 |

38 | 44.25 | 2.12 | 40.25 | 4.88 | 39.25 | 0.38 | 38.12 | Specified by | 290 | 42.12 | 40 | 1.12 |

40 | 46.25 | 2.19 | 42.5 | 5.06 | 41.31 | 0.38 | 40.12 | Specified by | 310 | 44.12 | 44 | 1.12 |

42 | 48.25 | 2.31 | 44.5 | 5.25 | 43.38 | 0.44 | 42.12 | Specified by | 345 | 46.12 | 48 | 1.12 |

44 | 50.25 | 2.38 | 46.5 | 5.38 | 45.38 | 0.44 | 44.12 | Specified by | 370 | 48.12 | 52 | 1.12 |

46 | 52.81 | 2.44 | 48.62 | 5.69 | 47.44 | 0.44 | 46.12 | Specified by | 435 | 50.56 | 40 | 1.25 |

48 | 54.81 | 2.56 | 50.75 | 5.88 | 49.5 | 0.44 | 48.12 | Specified by | 480 | 52.56 | 44 | 1.25 |

50 | 56.81 | 2.69 | 52.75 | 6.06 | 51.5 | 0.44 | 50.12 | Specified by | 520 | 54.56 | 48 | 1.25 |

52 | 58.81 | 2.75 | 54.75 | 6.19 | 53.56 | 0.44 | 52.12 | Specified by | 550 | 56.56 | 52 | 1.25 |

54 | 61 | 2.81 | 56.75 | 6.38 | 55.62 | 0.44 | 54.12 | Specified by | 620 | 58.75 | 56 | 1.25 |

56 | 63 | 2.88 | 58.75 | 6.56 | 57.69 | 0.56 | 56.12 | Specified by | 650 | 60.75 | 60 | 1.25 |

58 | 65.94 | 2.94 | 60.75 | 6.88 | 59.69 | 0.56 | 58.12 | Specified by | 780 | 63.44 | 48 | 1.38 |

60 | 67.94 | 3 | 63 | 7.06 | 61.81 | 0.56 | 60.12 | Specified by | 850 | 65.44 | 52 | 1.38 |

The difference between ASME B16.47 Series A and Series B flanges

Generally speaking, ASME B16.47 Series A flanges are much thicker, heavier and stronger than Series B flanges in the same size and pressure rating thus can withstand more external loading than Series B type. Series B flanges need more but smaller fasteners (bolts & nuts) than Series A flanges and have a smaller bolt circle diameter than that of Series A flanges. The smaller the bolt circle diameter is, the less flange movement tends to occur. Both Series A and Series B define weld neck flanges and blind flanges in raised face type(RF) but only Series A defines ring type joint(RTJ) flanges from Class 300 through Class 900 within this standard. From a commercial point of view, ASME B16.47 Series A flanges are more expensive than Series B flanges. Most piping end users or designers may choose Series A flanges for the new pipeline or equipment. But if you are doing some refurbishment/replacement job or non-critical piping design, Series B flanges are more popular.

Inquiry