Extensive Experience

With years of industry experience, we has built a solid reputation for delivering top-notch products and exceptional customer service. Our team consists of highly skilled professionals who understand the complexities of different industries and can provide expert advice and guidance.

Exceptional Quality

We source our materials from trusted suppliers and subject them to rigorous quality control checks. This ensures that our flanges are durable, reliable, and able to withstand the most demanding conditions.

Customization Options

We understand that every project is unique, and sometimes, standard flanges may not meet your specific requirements. That's why we offer customization options to tailor our products to your exact needs. Our skilled engineers can work closely with you to develop custom flanges that fit perfectly into your application.

Competitive Pricing

We strive to offer competitive pricing without compromising on the quality of our products. Our cost-effective solutions ensure that you get the best value for your investment.

Steel pipes are cylindrical tubes made from steel that are used many ways in manufacturing and infrastructure. They're the most utilized product made by the the steel industry. The primary use of pipe is in the transport of liquid or gas underground—including oil, gas, and water.

Durability

There are two main uses for steel pipes in construction – structural and transportation. For structural purposes, steel pipes are inserted deep underground before the foundation is laid to provide stability. If you see a disruption in your local area, then those are most likely because construction workers are laying steel pipes.As for transportation, steel pipes are used for oil, gas, sewage, and water. In other projects, it supports the flow of hazardous chemicals as well. In some cases, steel pipes are used as bollards to protect establishments and people from vehicle-ramming accidents.All of these applications demand the durability of materials. This is where the strength of steel pipes is a desirable advantage.

Resistance to Corrosion

Corrosion is arguably one of the most common problems in construction. After all, it leads to compromising the structural integrity of projects. Unlike other pipes, steel pipes are ideal to work with because of their resistance to corrosion.For example, plastic pipes that experienced wear and tear may no longer be conducive for application. Copper pipe fittings are not corrosion-resistant, making them more likely to pose dangers to entire structures.With a corrosion-resistant layer, it’s far safer to continue using steel pipes. They would be able to maintain superior performance quality, making them perfect for high-pressure applications.

Easily Malleable

Builders seek materials that are easy to fabricate because it gives them freedom in terms of construction planning. It can also mean reduced physical waste during last-minute changes.As a material, steel is flexible. It is a metal used to achieve numerous construction needs because it is highly malleable. This property refers to a material’s ability to be formed into different shapes without breaking.Steel pipes have high tensile strength, making it perfect for supporting all kinds of structures. Rest assured that it will not suffer from breakage when you use it for your projects.

Recyclable

With an alarming rise in environmental problems, contractors and builders are being called upon to reduce waste and make use of recyclable materials. This is where a steel pipes’ recyclability makes it advantageous to work with.Steel is the most recycled material on the planet. In fact, it is more recyclable than all the other materials combined. It retains an 86% recycling rate. According to a study, a staggering 69% of steel gets recycled after use in North America alone.When the pipes are no longer needed, they can simply be melted down and be used from one product to another. Its property allows it to be recycled continually with no degradation in performance quality.

Cost Efficient

Using steel pipes can help you cut down on different construction project costs.Given its innate strength, a small amount of the metal goes a long way in supporting foundations.In addition, steel pipes are significantly cheaper than other materials. Its price has remained low because manufacturers are making use of recycled steel to create new products.

Carbon Steel Pipe: This is the most commonly used type of steel pipe due to its affordability and versatility. Carbon steel pipes are made from an alloy of iron and carbon and are known for their high strength and durability. They are used in various applications such as water transportation, plumbing, and structural framework.

Stainless Steel Pipe: Stainless steel pipes are highly resistant to corrosion and have excellent strength and durability. They are made from an alloy of iron, chromium, and other elements. Stainless steel pipes are used in industries that require resistance to chemical corrosion, such as oil and gas, food processing, and pharmaceuticals.

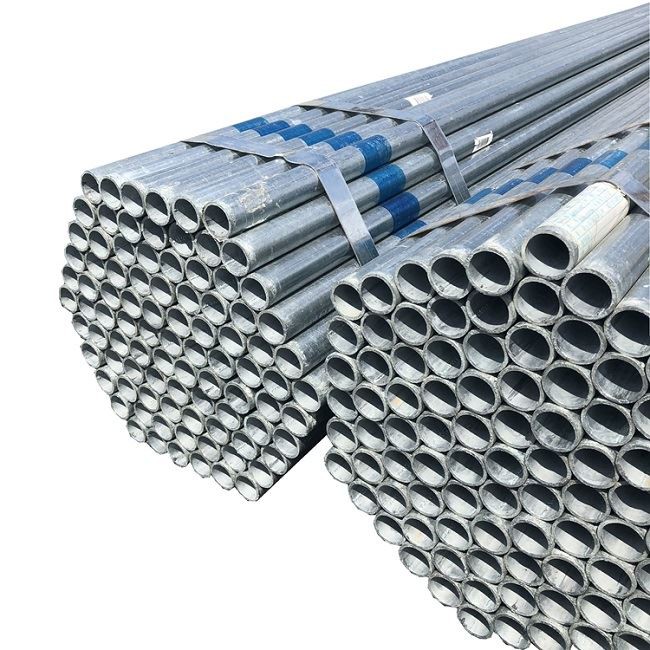

Galvanized Steel Pipe: Galvanized steel pipes are coated with a layer of zinc to prevent corrosion. This type of pipe is commonly used in areas with high humidity or exposure to the elements. Galvanized steel pipes are widely used in plumbing, water distribution, and agriculture.

Seamless Steel Pipe: As the name suggests, seamless steel pipes are manufactured without any welded joints, resulting in a smooth and continuous surface. This makes them ideal for applications that require high pressure or a tight seal, such as oil and gas transmission, hydraulic systems, and boiler tubes.

Welded Steel Pipe: Welded steel pipes are made by bending and welding steel plates or strips. They are commonly used in industries that require large quantities of steel pipes, such as construction, oil and gas transportation, and structural support.

Alloy Steel Pipe: Alloy steel pipes are made from a combination of different metals, such as chromium, nickel, and manganese. They offer higher strength, resistance to corrosion, and temperature stability compared to carbon steel pipes. Alloy steel pipes are used in industries that require specific mechanical properties, such as aerospace, automotive, and power plants.

Ductile Iron Pipe: Although not technically steel, ductile iron pipe is often grouped with steel pipes due to its similar characteristics and applications. Ductile iron pipes are known for their high tensile strength, flexibility, and corrosion resistance. They are commonly used in water and wastewater transportation, as well as in structural applications.

In the construction industry, steel pipes are extensively employed for building structures such as bridges, high-rise buildings, and stadiums. The high strength and resistance to extreme weather conditions make steel pipes ideal for such projects. Steel pipes can also be used to reinforce foundations and underground structures, ensuring their stability and longevity.

Another important application of steel pipes is in the transportation of fluids and gases. They are used in the oil and gas industry to transport petroleum, natural gas, and other fluids over long distances. The seamless structure of steel pipes minimizes the risk of leakage and ensures efficient and safe transportation. Steel pipes are also widely utilized in water supply systems, as they are corrosion-resistant and can withstand high pressure.

Steel pipes find extensive use in the manufacturing industry as well. They are employed in the production of machinery and equipment, facilitating the efficient transfer of liquids, gases, and raw materials within manufacturing processes. Steel pipes are also crucial components in heating, ventilation, and air conditioning (HVAC) systems, ensuring the proper distribution of cooled or heated air in buildings.

Steel pipes are utilized in the agricultural sector for irrigation purposes. Large-diameter steel pipes are used to transport water from sources such as rivers or reservoirs to agricultural fields, providing a reliable water supply for crops. The durability of steel pipes helps withstand the harsh outdoor conditions, ensuring uninterrupted water flow.

In the automotive industry, steel pipes have numerous applications. They are used in the exhaust systems of vehicles, allowing for efficient emission of exhaust gases. Steel pipes are also employed in the chassis and frame construction of automobiles, providing strength and structural integrity.

Point 1

The first stage in the process is raw material preparation. High-quality steel is selected, usually in the form of large coils or sheets. These raw materials undergo inspection and testing to ensure they meet the required specifications. Any defects or impurities are carefully removed.

Point 2

Once the raw materials have been prepared, the next step is forming. This process involves passing the steel through various machines, such as rollers, to shape it into a cylindrical form. Depending on the desired diameter and thickness of the pipe, different machines and techniques may be used.

Point 3

After forming, the steel pipe enters the welding stage. This is where the edges of the steel strip are joined together to form the pipe's longitudinal seam. Two common methods used for welding are the high-frequency electric resistance welding (HF-ERW) and submerged arc welding (SAW). These techniques ensure a strong and secure bond between the edges.

Point 4

Following welding, the pipe undergoes further processing to improve its mechanical properties. One such step is heat treatment, where the pipe is heated and cooled to optimize its strength and hardness. This process helps eliminate residual stresses and enhances the pipe's resistance to corrosion and other forms of damage.

Point 5

Once the pipe has been heat-treated, it goes through a series of finishing processes. These include sizing, straightening, and cutting to the desired length. The pipe may also be subjected to non-destructive testing to detect any defects or irregularities.

Point 6

At this stage, the steel pipe is ready for surface treatment, which involves cleaning, degreasing, and coating. This process helps protect the pipe from rust and corrosion, making it suitable for various applications, including transportation of fluids or gas.

Point 7

Pipes undergo quality control inspections to ensure they meet the required standards. This involves conducting a range of tests, such as dimensional checks, visual inspections, and mechanical property tests. Any pipes that do not meet the specified criteria are rejected, and only the ones that pass the inspections move on to packaging.

Point 8

The last step in the process is packaging and storage. The steel pipes are carefully bundled, usually in packs or stacks, and securely wrapped to prevent any damage during transportation. They are then stored in warehouses or shipped directly to customers, ready for use in various industries, such as construction, oil and gas, and plumbing.

Iron Ore: The primary raw material in the production of steel pipe is iron ore. Iron ore is mined from the earth and undergoes a series of processing steps, including crushing, grinding, and heating, to extract the iron content. The quality and purity of iron ore greatly impact the quality of the final steel pipe product.

Carbon: Carbon is another vital component of steel pipe. It is added to iron during the manufacturing process to improve key properties such as strength, hardness, and resilience. The carbon content in steel pipes can vary depending on the intended application, with higher carbon content resulting in stronger and harder pipes.

Alloying Elements: In addition to carbon, steel pipe may contain various alloying elements. Alloying elements such as chromium, nickel, and manganese are added in specific quantities to enhance specific properties of the steel, such as corrosion resistance, heat resistance, or high-temperature strength. These elements are carefully selected based on the desired characteristics of the final steel pipe product.

Impurities: Despite the comprehensive refining processes, steel pipe may still contain small amounts of impurities. These impurities can include sulfur, phosphorous, and trace elements that were present in the iron ore or introduced during the manufacturing process. Manufacturers take great care to minimize these impurities as they can negatively impact the strength and integrity of the steel pipe.

Manufacturing Process: The components of steel pipe are carefully combined through a series of manufacturing processes. These processes include melting the iron ore, adding carbon and alloying elements, shaping the molten steel into the desired form, and then cooling and solidifying it. The manufacturing process also involves heat treatments and various finishing techniques to further enhance the properties and appearance of the steel pipes.

Coatings: Depending on the specific application and environment, steel pipes may also have additional protective coatings. These coatings, such as paint, epoxy, or zinc, provide an extra layer of protection against corrosion, abrasion, and other forms of damage. These coatings prolong the lifespan of the steel pipe and enhance its performance in challenging conditions.

What you should know when use Steel Pipe

Material Selection

Pipe Size and Thickness

Corrosion Protection

Proper Installation

Regular Maintenance

Safety Precautions

Compliance with Regulations

Maintenance Tips for Steel Pipe

Inspection and Cleaning: Regularly inspect the steel pipes for any signs of corrosion, rust, or damage. Clean the pipes with a suitable cleaning solution to remove any dirt, dust, or debris that may have accumulated over time. This will help prevent further corrosion and extend the lifespan of the pipes.

Apply Protective Coatings: To enhance the corrosion resistance of steel pipes, apply protective coatings such as zinc or epoxy. These coatings act as a barrier between the pipe surface and the surrounding environment, preventing corrosion and rust formation. Prioritize areas that are more prone to corrosion, such as joints and bends.

Prevent Water Accumulation: Accumulated water can lead to corrosion and weaken the steel pipes over time. Regularly inspect the pipes for any signs of water accumulation or leakage, particularly in areas exposed to moisture or prone to condensation. Ensure proper drainage and install moisture barriers, if necessary, to minimize water contact with the pipes.

Maintain Proper Insulation: Insulation plays a crucial role in maintaining the integrity of steel pipes, particularly in extreme temperatures. Insulate the pipes in areas where temperature fluctuations are common to prevent thermal expansion and contraction, which can lead to stress and potential damage. Use suitable insulation materials to ensure optimal performance.

Implement Preventive Measures: To prevent damage caused by external factors, consider implementing preventive measures such as installing protective guards or barriers around the pipes. This will help safeguard the pipes from accidental impact, potential chemical exposure, or other sources of physical damage.

Regular Monitoring and Repairs: Continuously monitor the performance of the steel pipes and promptly address any signs of deterioration or damage. Conduct regular inspections and carry out necessary repairs or replacements as soon as possible to prevent further deterioration and potential failures.

Follow Manufacturer Guidelines: Always adhere to the manufacturer's guidelines for the specific steel pipes being used. This includes recommendations for maintenance, cleaning, and any other specific requirements. Following these guidelines will ensure that the pipes operate at their optimum level and maintain their durability over time.

EO flange co.,Ltd. established in 1991 and in charge of commercial area with more than 20 years' experience in manufacturing, stocking, processing and exporting flanges. Our company annually produces 5,000 tons of finished flanges and pipe fittings made from stainless steel, carbon steel, alloy steel, dual-phase steel and many other materials. The products have been exported to 28 countries and areas, such as Japan, America, France, Germany, Italy, etc. With self-run import & export right, the company is capable of directly taking foreign customers' orders, producing standard flanges in accordance with ANSI, DIN, ASME and GOST domestic and international standards, and producing ring-type forgings, non-standard flanges and pipe fittings according to customers' drawings or samples.

Q: What are the requirements for steel pipe?

Q: What are the 3 grades of steel pipe?

Q: How long will steel pipe last in water?

Q: What type of pipe is strongest?

Q: What are the different types of steel pipes?

Q: What is the difference between seamless and welded steel pipes?

Q: What are steel pipes used for?

Q: How are steel pipes made?

Q: What is the advantage of using steel pipes?

Q: What is the difference between black steel pipe and galvanized steel pipe?

Q: Can steel pipes be recycled?

Q: How do I choose the right steel pipe for my project?

Q: How are steel pipes measured?

Q: What is the maximum operating temperature for steel pipes?

Q: Can steel pipes be used for underground applications?

Q: Can steel pipes be used for high-pressure applications?

Q: What are the common standards for steel pipes?

Q: Are there any environmental concerns related to steel pipes?

Q: How do I maintain steel pipes?

Q: Can steel pipes be used in extreme weather conditions?