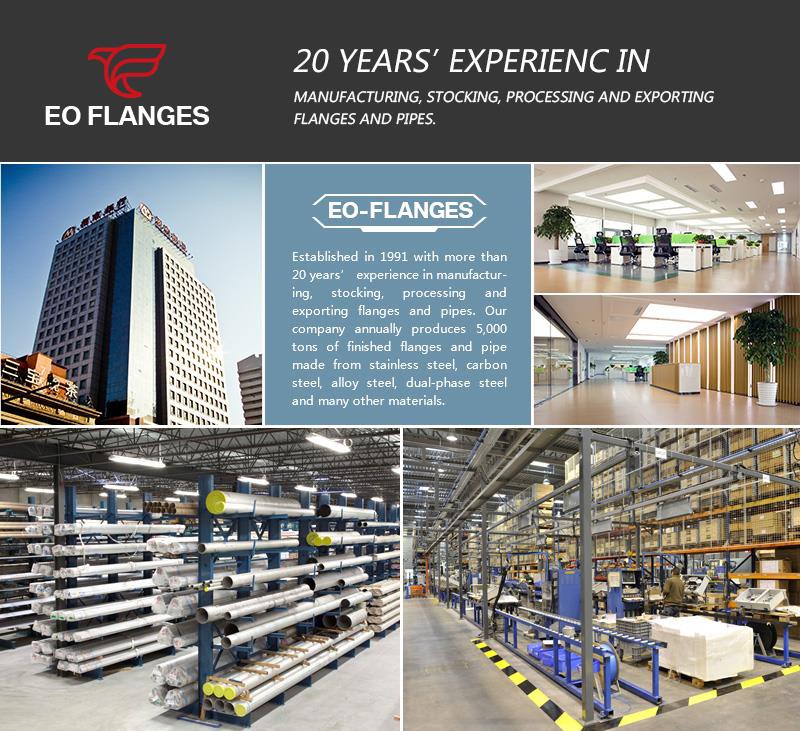

Extensive Experience

With years of industry experience, we has built a solid reputation for delivering top-notch products and exceptional customer service. Our team consists of highly skilled professionals who understand the complexities of different industries and can provide expert advice and guidance.

Exceptional Quality

We source our materials from trusted suppliers and subject them to rigorous quality control checks. This ensures that our flanges are durable, reliable, and able to withstand the most demanding conditions.

Customization Options

We understand that every project is unique, and sometimes, standard flanges may not meet your specific requirements. That's why we offer customization options to tailor our products to your exact needs. Our skilled engineers can work closely with you to develop custom flanges that fit perfectly into your application.

Competitive Pricing

We strive to offer competitive pricing without compromising on the quality of our products. Our cost-effective solutions ensure that you get the best value for your investment.

A butterfly valve is a shut-off valve with a relatively simple construction. In closed position, the disc blocks the valve bore while in open position, the disc is turned to allow flow. A quarter turn takes the valve from fully open to fully closed position, or opposite, and thus the butterfly valve allows for quick opening and closure.

Compact design

One of the primary benefits of butterfly valves is their compact and lightweight design. Compared to other types of valves, such as gate valves or ball valves, butterfly valves take up less space and are easier to install. Their lightweight construction means that they require less structural support, making them ideal for applications where weight is a concern.

Ease of operation

Another advantage of butterfly valves is their ease of operation. These valves have a simple mechanism that allows for quick opening and closing. With just a quarter-turn of the handle or a lever, the valve can fully open or close, resulting in efficient flow control. This simplicity in operation makes butterfly valves suitable for both manual and automated systems.

Excellent flow control capabilities

Butterfly valves also offer excellent flow control capabilities. Their spherical disc or plate design enables a streamlined flow path, reducing turbulence and pressure drop. The full-bore design of butterfly valves allows for unrestricted flow, resulting in minimal resistance and improved efficiency. Additionally, butterfly valves can be used for throttling applications, allowing precise control of the flow rate.

Durable

Furthermore, butterfly valves are highly reliable and provide tight shut-off. The construction of these valves ensures a tight seal, preventing any leakage. This characteristic is particularly important in applications where the fluid needs to be completely blocked off to avoid contamination or for safety purposes. The durable materials used in butterfly valves make them resistant to wear and corrosion, guaranteeing a long service life.

Easy to maintain

Maintenance of butterfly valves is relatively easy and cost-effective. Their simple design allows for easy access to the internal components, making inspection and repair work convenient. Additionally, the few parts present in butterfly valves result in reduced maintenance costs and downtime.

Versatility

The versatility of butterfly valves is another advantage worth mentioning. These valves can be used in a wide range of industries, including petroleum, chemical, water treatment, HVAC, and food processing. They are suitable for both high and low-pressure applications, making them a preferred choice for many industries.

Wafer Butterfly Valve: The wafer butterfly valve is the most common type of butterfly valve. It is designed to fit between two flanges in a pipe system. This type of valve is lightweight, compact, and less expensive compared to other types. It is ideal for low-pressure applications, and its simple design allows for easy installation and maintenance.

Lug Butterfly Valve: The lug butterfly valve has threaded inserts on both sides of the valve's body. These inserts allow the valve to be installed using bolts without needing nuts. This design makes it easier to install and remove the valve without having to disconnect the entire system. The lug butterfly valve is often used in applications that require frequent maintenance or where space is limited.

Double Offset Butterfly Valve: The double offset butterfly valve is designed to provide better sealing with reduced friction. It has an offset shaft, which means the axis of rotation is located behind the seal. This design reduces wear and tear on the seal, resulting in a longer lifespan and improved performance. Double offset butterfly valves are commonly used in high-pressure applications and industries such as oil and gas.

Triple Offset Butterfly Valve: The triple offset butterfly valve is a more advanced type of butterfly valve that offers excellent sealing performance and durability. It has three offsets: the first offset is the axis of rotation, the second offset is the position of the shaft relative to the seal, and the third offset is the cone shape of the sealing surface. This design allows for a bubble-tight seal, even under high-pressure conditions. Triple offset butterfly valves are commonly used in industries that require tight shut-off and reliable performance, such as power plants and chemical processing.

High-Performance Butterfly Valve: High-performance butterfly valves are designed to handle extreme conditions, including high pressures and temperatures. They are usually made of high-grade materials such as stainless steel or alloy, allowing them to withstand corrosive media and harsh environments. These valves are often used in applications where a tight shut-off is required, such as power plants, refineries, and petrochemical industries.

Application of Butterfly Valve

Regulating Fluid Flow: Butterfly valves are widely used for regulating fluids. As a regulating valve, this is done through the action of the actuator that communicates with the stem and disc assembly of the valve. The degree of angular opening translates to an exact amount of fluid that goes through the valve. Thus, the flow rate of the system is controlled through the actuators.Actuators can be manual or automatic. To control a regulating valve remotely, it must have a flow controller. This controller will automatically translate information to the valve mechanism to open or close based on the flow rate of the system.

Flow Isolation: Butterfly valves can be used for flow isolation because of their lightweight feature, easy manipulation and quarter-turn action.

However, when you use a butterfly valve as an isolation valve, you need to make sure that it would not negatively affect your system performance.That is why care should be taken when using this type of valve as an isolation valve. System losses should be accounted for in calculations to maintain a good system performance.

Backflow Prevention: Some food manufacturing processes require aggressive wash down procedures in which butterfly valves can be used for backflow prevention during this process. Backflow prevention is necessary as food processing plants should be clean and operate in extremely sanitary conditions.

As Throttling Valves: Butterfly valves are commonly used for regulating large fluid flows, including viscous slurries, but it should be noted that they are not a good choice for precision throttling.

For Constant Load Applications: Butterfly valves can handle large volumes of fluids but are sensitive to load changes in the system. This type of valve has a limited capacity in handling small load changes. Allowing a few millimeters opening can be equivalent to a large volume difference.

For Space-Restrictive Applications: One of the best features of butterfly valves is it is economical and space-saving. Systems with space restrictions can benefit from butterfly valves as compared with ball valves.

For Liquids and Gases: Butterfly valves can generally handle liquids and gases and even slurries, but not bulk solids. This is because dry bulk solids are abrasive and can erode the material (and seal) of the butterfly valve. Plus, butterfly valves are inefficient for delivering solids as its disc can create a restriction for the flow of solids.

Butterfly valves are widely used in various industries and play a crucial role in controlling the flow of fluids.The first step in the process of butterfly valve is the selection of the appropriate valve for a specific application. There are different types of butterfly valves available, such as wafer style, lug style, and double-flanged style. The selection depends on factors like the pressure and temperature of the fluid, the size of the valve, and the requirements of the system.

Once the suitable valve is selected, the installation process begins. It involves mounting the valve between two flanges using bolts and nuts. The valve is positioned in such a way that the disc is in the center of the pipe, allowing for smooth flow control.

After the installation, the butterfly valve is ready for operation. The valve can be manually operated or automated depending on the requirements. In manual operation, the operator uses a handle or a lever to control the position of the disc. This, in turn, regulates the flow of the fluid. In automated operation, the valve is equipped with an actuator, which can be pneumatic, electric, or hydraulic. The actuator controls the movement of the disc based on signals received from the control system.

During the operation of the butterfly valve, the disc rotates inside the valve body. When the valve is fully open, the disc is positioned parallel to the flow direction, allowing maximum flow. When the valve is closed, the disc is rotated perpendicular to the flow direction, blocking the flow completely.

Maintenance is an essential part of the process of butterfly valve. Regular inspection and lubrication are necessary to ensure the proper functioning of the valve. If any damage or wear is detected, it should be repaired or replaced promptly to avoid any potential leakage or performance issues.

Made from a tough and rigid material, the valve body houses and protects the disc and other internal components of the butterfly valve. It links the valve to the piping system and to the external operating mechanism that controls the disc.

Disc. The disc permits, regulates, and stops the flow of the fluid in the pipeline. Flow is controlled by the rotary motion of the disc. The discharge flow rate depends on the degree of disc opening.

When the disc is perpendicular to the flow’s cross-sectional area, the fluid is fully obstructed from flowing out of the valve. Otherwise, the fluid is permitted to flow through the space between the seat and the disc. It takes a 90° rotation from the closed position of the disc to allow full opening or closing of the valve. Flow is throttled when the disc is rotated less than 90°.

The stem is a shaft that connects the disc to the external operating mechanism. It is sealed by O-rings and bushings to prevent fluid leakage. The stem can be made from a one-piece shaft or two-piece (split-stem) shaft. The placement of the stem axis and its connection to the disc depends on the type of butterfly valve.

Seat or Sealing Ring: The valve seat for basic concentric butterfly valves is a ring that provides sealing between the disc edge and the valve body when it is in a closed position. Its sealing action is necessary to avoid leakage of any fluid to the discharge of the butterfly valve. Since the disc slides on the surface of the seat during valve opening, it must be made from a material with a low coefficient of friction.

The external operating mechanism of a butterfly valve controls the fluid flow across the valve. It may be operated by manual rotation of the stem or by automatic actuation.

Manual operation of butterfly valves involves the application of torque to the lever or handwheel attached to the stem. Levers can set the valve into a closed, fully-opened, or partially-opened position. Larger butterfly valves are equipped with handwheels and gearboxes to increase torque and to aid in the opening and closing of the valve.

Tripled offset has three eccentrics each of which is located differently in the valve. The eccentrics are placed in an offset position to form an offset conical profile creating a right angle cone.

Triple Offset Eccentrics

The quality and type of bushing determines the longevity of a butterfly valve. The best bushings are resistant to corrosion and wear and used for precision control, current limiting, and switching of chemicals, petrochemicals, chlorine, paper production, and electroplating. Bushings are made from a variety of materials with many types being self lubricating for enhanced performance of the butterfly valve.

Material of Butterfly Valve

Stainless Steel

Carbon Steel

Hastelloy

Brass

Nickel Alloys

Titanium Alloys

Nickel Aluminum Bronze

Regular Inspection

Periodic inspection is crucial to identify any signs of wear, corrosion, or leakage. Inspect the valve body, disc, stem, and sealing components for any visible damage. Look for signs of buildup or clogging in the valve assembly as well.

Lubrication

Proper lubrication is essential to reduce friction and ensure smooth operation of the valve. Apply a suitable lubricant to the stem, disc, and sealing surfaces as recommended by the manufacturer. Regularly lubricate the valve to prevent excessive wear and tear.

Cleaning

Debris, sediments, or foreign particles can cause sticking or sealing issues in the valve. Clean the valve regularly to remove any buildup that can hinder the valve's performance. Use a mild solvent or cleaning agent to remove deposits from the valve components.

Sealing Inspection

Inspect the sealing components of the butterfly valve, including the seat and gasket, for any signs of deterioration. Replace any damaged or worn-out sealing elements to maintain a proper seal. A faulty seal can result in leakage or inefficient operation of the valve.

Valve Operation

Operate the valve periodically to prevent it from becoming stiff or seizing. Open and close the valve fully to ensure smooth movement and proper functioning. Avoid forcing or jamming the valve, as it can damage the internal components.

Bolts and Fasteners

Check the bolts and fasteners securing the valve to the pipeline or equipment. Ensure that they are tight and properly torqued. Loose or damaged bolts can cause misalignment or leakage, compromising the valve's efficiency.

Pressure Testing

Conduct regular pressure tests on the butterfly valve to assess its integrity. This will help identify any potential leaks or weaknesses in the valve assembly. Follow the manufacturer's guidelines when performing pressure tests.

Professional Maintenance

For complex or critical applications, it is advisable to seek professional maintenance services. Certified technicians can perform in-depth inspections, repairs, and necessary adjustments to ensure the valve's optimal performance and safety.

EO flange co.,Ltd. established in 1991 and in charge of commercial area with more than 20 years' experience in manufacturing, stocking, processing and exporting flanges. Our company annually produces 5,000 tons of finished flanges and pipe fittings made from stainless steel, carbon steel, alloy steel, dual-phase steel and many other materials. The products have been exported to 28 countries and areas, such as Japan, America, France, Germany, Italy, etc. With self-run import & export right, the company is capable of directly taking foreign customers' orders, producing standard flanges in accordance with ANSI, DIN, ASME and GOST domestic and international standards, and producing ring-type forgings, non-standard flanges and pipe fittings according to customers' drawings or samples.

Q: In what conditions a butterfly valve is recommended?

Q: What is the most common use of butterfly valve?

Q: What causes a butterfly valve to fail?

Q: Does it matter which way a butterfly valve is installed?

Q: How do you tell if a butterfly valve is open or closed?

Q: How much pressure can a butterfly valve handle?

Q: What is the pressure limit for a butterfly valve?

Q: Can you repair a butterfly valve?

Q: How many turns does it take to open a butterfly valve?

Q: Is there a flow on a butterfly valve?

Q: Can you lock a butterfly valve?

Q: Do butterfly valves restrict flow?

Q: What is the flow direction of a butterfly valve?

Q: How do you pressure test a butterfly valve?

Q: Can you throttle a butterfly valve?

Q: What is a seal ring on a butterfly valve?

Q: What is butterfly valve basics?

Q: Can you hot tap a butterfly valve?

Q: Should a butterfly valve be vertical or horizontal?

Q: Does butterfly valve prevent backflow?