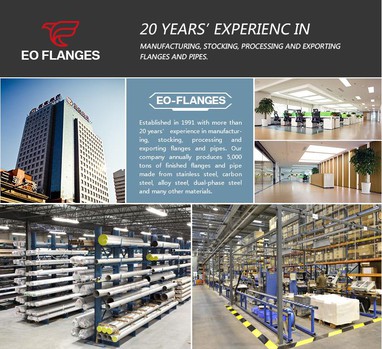

Extensive Experience

With years of industry experience, we has built a solid reputation for delivering top-notch products and exceptional customer service. Our team consists of highly skilled professionals who understand the complexities of different industries and can provide expert advice and guidance.

Exceptional Quality

We source our materials from trusted suppliers and subject them to rigorous quality control checks. This ensures that our flanges are durable, reliable, and able to withstand the most demanding conditions.

Customization Options

We understand that every project is unique, and sometimes, standard flanges may not meet your specific requirements. That's why we offer customization options to tailor our products to your exact needs. Our skilled engineers can work closely with you to develop custom flanges that fit perfectly into your application.

Competitive Pricing

We strive to offer competitive pricing without compromising on the quality of our products. Our cost-effective solutions ensure that you get the best value for your investment.

A ball valve is a flow control device which uses a hollow, perforated, and pivoting ball to control fluid flowing through it. It is open when the hole through the middle of the ball is in line with the flow inlet, and closed when it is pivoted 90 degrees by the valve handle, blocking the flow.

Excellent Shut-off Capability

Ball valves provide a tight seal, ensuring complete shut-off and preventing leakage. The spherical closure design of ball valves allows for a reliable and secure shut-off, even in high-pressure systems.

Quick and Easy Operation

They have a simple design and are easy to open and close, requiring a quarter turn of the handle or lever. This quick operation saves time and allows for efficient control of fluid flow.

Minimal Pressure Drop

Ball valves have low friction loss, resulting in minimal pressure drop across the valve. This characteristic is essential in applications where maintaining system pressure is crucial, as it helps minimize energy consumption and ensures efficient flow control.

Wide Range of Applications

Ball valves are suitable for various industries, including oil and gas, chemical, water treatment, and HVAC systems. Their versatility stems from their ability to handle a wide range of temperatures, pressures, and fluid types.

Good Flow Control

Ball valves offer precise control over the flow rate, allowing for smooth operation and modulation. The quarter-turn operation and the ability to achieve full or partial flow make them effective in controlling the flow of fluids in both simple and complex systems.

High Efficiency

The extraordinary efficiency of ball valves is undeniable. The risk of leakage associated with ball valves is minimal due to their full-proof sealing. No matter what kind of ball valve you are using, there is always a guarantee of excellent functionality. Ball valves cannot only control the high-pressure flow of liquids and gases but also regulate low-pressure flow effectively.

Low Maintenance

Ball valves require low-maintenance compared to other types of valves. The simple mechanism of ball valves makes them less prone to wear and tear. The use of a pivot concentrates all the friction on one part of the valve saving the rest of the parts.

Robustness

The ball valves are considered one of the strongest types of valves. They have an enormous ability to withstand great amounts of pressure and temperature. The material used in ball valves is less prone to corrosion and damage. That is why ball valves can be used extensively in all kinds of environmental conditions.

Full Port Ball Valve

A full port ball valve, also known as a full bore ball valve, has an oversized ball and a larger opening, allowing for maximum flow capacity. It provides minimal friction loss and pressure drop, making it ideal for applications that require high flow rates or low pressure drops. However, full port ball valves are bulkier and more expensive compared to standard port ball valves.

Standard Port Ball Valve

Standard port ball valves have a reduced-sized ball and a smaller opening compared to full port ball valves. They are commonly used in applications where flow control is not a primary concern. The smaller opening results in a higher velocity flow, which can lead to increased pressure drop. Standard port ball valves are more compact and cost-effective, making them suitable for most general-purpose applications.

V-port Ball Valve

V-port ball valves have a V-shaped ball with an eccentric bore. This design provides accurate flow control by allowing the ball to rotate partially, thereby varying the flow area. V-port ball valves are commonly used in applications that require precise control of flow rates or for throttling purposes. They are often preferred in industries such as chemicals, pharmaceuticals, and wastewater treatment.

Reduced Port Ball Valve

A reduced port ball valve has a smaller port size compared to the pipe size, resulting in reduced flow capacity. They are typically used in applications where reducing the flow rate is desired, such as flow control or regulation. Reduced port ball valves are commonly used in the oil and gas industry, as well as in industries that require precise flow control.

Trunnion Ball Valve

Trunnion ball valves are designed with a trunnion or a support mechanism at the bottom of the ball. This mechanism supports the weight of the ball and reduces the operating torque. Trunnion ball valves are commonly used in high-pressure or high-temperature applications, where large sizes are required. They provide better sealing and can handle higher flow rates compared to floating ball valves.

Floating Ball Valve

Floating ball valves rely on the pressure of the fluid to create a seal between the ball and the seat. The ball is free to move or float, allowing it to self-align with the seat and create a tight seal. Floating ball valves are commonly used in low-pressure applications and are less expensive compared to trunnion ball valves.

Oil and Gas Industry

Ball valves are extensively used in the oil and gas industry for their durability and reliability. They are used in pipeline transportation systems, refineries, and petrochemical plants. These valves help in controlling the flow of crude oil, natural gas, and other petroleum products.

Water and Wastewater Treatment

Ball valves find applications in water treatment plants for their ability to handle a wide range of liquids with different viscosities. They are used for flow regulation, diversion, and isolation purposes. Ball valves also play a crucial role in wastewater treatment systems, ensuring proper control and management of sewage flows.

Power Generation

Ball valves are used in power generation plants to control the flow of steam, water, and other fluids. They are used in boiler feedwater systems, steam turbine control systems, and cooling water systems. The ability to operate at high pressures and temperatures makes ball valves an ideal choice in power generation facilities.

Chemical Industry

In the chemical industry, ball valves are utilized for handling corrosive and aggressive fluids. They can withstand high pressure and temperature conditions, making them suitable for various applications. Ball valves are commonly used in chemical processing, chemical storage, and transportation systems.

HVAC Systems

Ball valves are widely used in heating, ventilation, and air conditioning (HVAC) systems. They control the flow of hot or cold water, steam, and refrigerants in these systems. Their compact design and ease of operation make them ideal for HVAC applications.

Pharmaceutical Industry

Ball valves have a significant role in the pharmaceutical industry, where strict regulations and sanitary requirements must be met. These valves are used for controlling the flow of pharmaceutical-grade fluids, ensuring the highest level of hygiene and safety.

Food and Beverage Industry

Ball valves play a crucial role in the food and beverage industry, where hygiene is of utmost importance. They are used for controlling the flow of ingredients, as well as regulating the cleaning and sterilization processes. Ball valves that comply with food-grade standards are preferred in this industry.

Aerospace Industry

Ball valves find applications in the aerospace industry for controlling fluid flow in aircraft fuel systems, hydraulic systems, and aerospace engines. The ability to handle high pressures and function in extreme temperature conditions makes ball valves suitable for aerospace applications.

The Using Steps of Ball Valve

Inspect the valve: Before using a ball valve, it is important to visually inspect it for any signs of damage or wear. Check for leaks, cracks, or any other defects that may affect its performance. If any issues are found, it is recommended to replace or repair the valve before using it.

Prepare the system: Ensure that the pipeline or system where the ball valve will be installed is properly prepared. This includes cleaning the pipes, removing any debris or obstructions, and making sure the system is turned off or depressurized.

Position the valve: Determine the desired position of the ball valve, whether it needs to be fully open, fully closed, or somewhere in between to regulate the flow. The lever or handle attached to the valve is usually used to control the position.

Open the valve: To open the ball valve, turn the lever or handle in a clockwise direction. This will rotate the ball inside the valve, allowing the flow of fluids or gases to pass through the pipe. Stop turning the handle once the desired position is reached.

Close the valve: To close the ball valve, turn the lever or handle in a counterclockwise direction. This will rotate the ball to the closed position, stopping the flow of liquids or gases through the pipe. Again, stop turning the handle once the valve is fully closed.

Monitor the valve: While the ball valve is in use, it is important to monitor it for any signs of leakage or abnormal behavior. If any issues are noticed, such as leaks or difficulty in operation, it is crucial to address them immediately to prevent further problems.

Maintain the valve: Regular maintenance is essential for the efficient and prolonged lifespan of a ball valve. This includes periodically lubricating the moving parts, inspecting for wear or damage, and replacing any worn-out or defective components.

All internal components of a ball valve are contained inside the valve housing or the body. Its primary function is to provide a secure and sealed enclosure for the ball, ensuring that the flow of fluids through the valve can be precisely controlled. The housing typically features inlet and outlet ports, allowing for the connection of pipes or pipelines. It is made of a hard and rigid metal, thermoplastic, or thermoplastic-lined metal that protects the components of the ball valve. This robust construction ensures the reliable operation and longevity of ball valves in various industrial applications.

The ball is a sphere that has a hole in its center. The hole in its center is called the bore. The bore serves as the flow opening of the fluid when the cross-section of the fluid flow path and the bore is coplanar. Otherwise, the flow is throttled. A ball valve may have a solid ball or a hollow ball. A solid ball has a constant opening diameter throughout its structure, which helps the fluid to smoothly flow at a constant velocity. A hollow ball, on the other hand, has a hollow internal structure, and the space inside it allows more fluid to pass through the valve. However, the larger space creates turbulence and high velocities. A hollow ball is more lightweight and cheap compared to a solid ball.

The shaft connects the ball to the control mechanism that rotates the ball. When the shaft is turned, it either aligns the ball with the valve's flow path to permit the flow of fluids or positions the ball perpendicular to the flow path to block it completely. The shaft has seals such as O-rings and packing rings to seal the shaft and the bonnet to avoid leakage of the fluid. The shaft's design and construction must be robust to withstand the pressure and temperature conditions of the system, ensuring reliable and efficient operation. The shaft may be manually operated by a lever or a handwheel or operated by an electric, pneumatic, or hydraulic actuation.

The bonnet is an extension of the valve housing that contains and protects the shaft and its packing, which is important in high-pressure and high-temperature applications. It may be welded or bolted to the body. It is also made of hard metal and it covers the opening made from connecting the shaft to the external control mechanism. The bonnet can be removable or integral to the valve body, depending on the valve design.

Ball valves have two seats, typically made of soft materials like PTFE (Teflon) or elastomers. These seats form a tight seal around the ball when the valve is in the closed position. They prevent leakage by creating a secure barrier between the ball and the valve body. The upstream seat seals against pressure, while the downstream seat seals against leakage to the atmosphere.

Brass: Brass is an alloy of copper and zinc that can be distinguished by its dull yellowish to reddish color, depending on the amount of zinc. It is the most common material for ball valves. Brass is a tough, strong, and durable metal that can withstand high temperatures and pressures. The copper in brass alloy has antimicrobial properties that inhibit the growth and reproduction of microbes on its surface. Brass has good chemical, corrosion, and biofouling resistance.

Stainless Steel: Stainless steel is a type of steel that contains higher chromium content and some amounts of nickel. The chromium content of stainless steel makes it acquire a superior corrosion resistance. Stainless steel is known for its excellent strength, toughness, and durability. It also retains its strength in high temperatures and pressures.

Polyvinyl Chloride (PVC): PVC is a tough, rigid and durable plastic material. Compared to brass and stainless-steel alloys, they generally have lower strength but they are cheaper. They are resistant to corrosion and most acids, bases, and salt solutions. However, they are not resistant to aromatic compounds and hydrocarbons. PVC ball valves (*) have a lower temperature and pressure rating, for up to 150 psi and 140°F, respectively. Application of PVC ball valves includes plumbing, irrigation, and water distribution systems.

Polypropylene Ball Valve (PP): PP is a tough, durable, lightweight, and flexible thermoplastic made from propylene monomer. It offers good resistance to most acids and bases, but has selective compatibility with organic substances and solvents. Its chemical resistance decreases with increasing temperatures. The maximum operating temperature of PP is 82°C. PP ball valves are suitable for regulating the flow of fluids with a wide range of viscosity. They are used as materials for ball valves in the manufacturing of sugar, fertilizers, chemicals, paper, and others.

Glass Fiber-Reinforced Polypropylene Ball Valve (GFPP): In GFPPs, glass fibers are reinforced to polypropylene to increase its dimensional stability, rigidity, and chemical resistance, and to reduce the PP’s coefficient of thermal expansion. Its heat deflection temperature is increased up to 1500C for a 40% GFPP at 264 psi. Reinforcement of glass fibers in PP increases cost-efficiency and makes it operate in more harsher and heavy-duty applications.

Polyvinylidene Difluoride Ball Valve (PVDF): PVDF is a high purity, durable, thermoplastic fluoropolymer with high molecular weight. It is synthesized from gaseous vinylidene fluoride monomer by a free-radical polymerization process. It is also resistant to abrasion.

Polyethylene (PE): PE is a durable, flexible, lightweight, and the most abundant thermoplastic. PE is compatible with most compounds, including strong acids and bases, and to some organic compounds including oils and alcohols. Its increasing crystallinity and density makes it more chemical resistant. PE ball valves are used in handling fluids in many manufacturing processes, as well as in water purification and wastewater treatment. The maximum operating temperature of PVDF is around 60°C.

Point 1: Crucial to determine the type of ball valve that meets your specific needs. There are several types available, including full port, reduced port, V-port, and trunnion ball valves. Full port valves provide unrestricted flow, making them ideal for applications where high flow rates are required. Reduced port valves, on the other hand, have a smaller ball opening, which reduces flow but also helps to reduce cost. V-port valves have a V-shaped ball opening that allows for better control of the flow. Trunnion ball valves, on the other hand, are suitable for high-pressure or high-temperature applications.

Point 2: Consider the material of the ball valve. The choice of material depends on the type of fluid being transported and the operating conditions. Common materials used for ball valves include brass, stainless steel, carbon steel, and PVC. Brass valves are suitable for water applications, while stainless steel valves are corrosion-resistant and can handle high temperatures and pressures. Carbon steel valves are best for applications involving oil and gas, while PVC valves are ideal for low-pressure applications.

Point 3: Consider the size and pressure rating of the ball valve. The size refers to the diameter of the ball valve, and it is important to choose the right size to ensure proper flow control. The pressure rating indicates the maximum pressure that the valve can handle. It is essential to select a ball valve with a pressure rating that is suitable for your specific application. Failure to do so can result in leaks, damages, or even accidents.

Point 4: Ake into account the certifications and standards that the ball valve complies with. In the industry, some commonly recognized certifications include ISO, API, ANSI, and ASME. These certifications ensure that the ball valve meets specific quality and safety requirements. Compliance with standards such as NACE, PED, or ATEX may also be necessary depending on the intended application.

Point 5: Consider the operating mechanisms of the ball valve. Ball valves can be operated manually, using a lever or a handwheel, or they can be automated with an actuator. Manual ball valves are simple and cost-effective, but they require manual intervention. Automated ball valves, on the other hand, provide remote control and can be integrated into a larger control system, but they are more expensive.

Point 6: Don't forget to consider the reputation and reliability of the manufacturer or supplier. Buying from a trusted and reputable source ensures that you receive a high-quality ball valve that meets your requirements and will last a long time.

EO flange co.,Ltd. established in 1991 and in charge of commercial area with more than 20 years' experience in manufacturing, stocking, processing and exporting flanges. Our company annually produces 5,000 tons of finished flanges and pipe fittings made from stainless steel, carbon steel, alloy steel, dual-phase steel and many other materials. The products have been exported to 28 countries and areas, such as Japan, America, France, Germany, Italy, etc. With self-run import & export right, the company is capable of directly taking foreign customers' orders, producing standard flanges in accordance with ANSI, DIN, ASME and GOST domestic and international standards, and producing ring-type forgings, non-standard flanges and pipe fittings according to customers' drawings or samples.

Q: Does it matter which way a ball valve goes?

Q: What is the most common application for a ball valve?

Q: Should ball valve be fully open?

Q: What is the main function of a ball valve?

Q: How do I choose a ball valve?

Q: How should a ball valve be installed?

Q: Can a ball valve be left partially open?

Q: Can a ball valve get stuck closed?

Q: Do ball valves prevent backflow?

Q: How do I know what size ball valve I need?

Q: How much psi can a ball valve handle?

Q: How long should a ball valve last?

Q: Can I use a ball valve for main water shut off?

Q: Can I repair a ball valve?

Q: What is the difference between a ball valve and a V ball valve?

Q: Should the ball valve be the same size as pipe?

Q: How often should ball valves be exercised?

Q: Can you over tighten ball valve?

Q: How do you check a ball valve?

Q: What is a ball valve also known as?