Product Details

Bolt hole diameter 1/8 in. larger than bolt diameter.

Standard bore dimensions provided. See bore chart for other wall thicknesses

This dimension is commonly associated with "true" lap joints. Industry standard is to make to the slip on length through the hub..

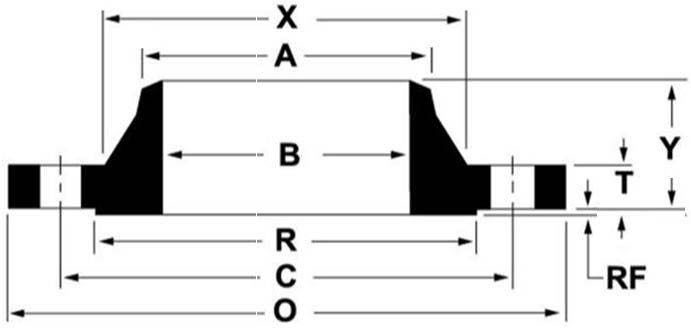

ANSI B16.5 Class 600 Welding Neck Flanges | |||||||||||

Nominal Pipe Size | Outside Diameter (O) | Thickness (T) | Raised Face Diameter (R) | Length Thru Hub (Y) | Point of Weld (A) | Hub Diameter (X) | Bore (B) | Approximate Weight (lbs) | Bolt Circle (C) | Number of Holes | Diameter of Holes |

1/2 | 3.75 | 0.56 | 1.38 | 2.06 | 0.84 | 1.5 | Specified by purchaser | 2 | 2.63 | 4 | 0.63 |

3/4 | 4.63 | 0.63 | 1.69 | 2.25 | 1.05 | 1.88 | Specified by purchaser | 4 | 3.25 | 4 | 0.75 |

1 | 4.88 | 0.69 | 2 | 2.44 | 1.32 | 2.13 | Specified by purchaser | 4 | 3.5 | 4 | 0.75 |

1 1/4 | 5.25 | 0.81 | 2.5 | 2.63 | 1.66 | 2.5 | Specified by purchaser | 6 | 3.88 | 4 | 0.75 |

1 1/2 | 6.13 | 0.88 | 2.88 | 2.75 | 1.9 | 2.75 | Specified by purchaser | 8 | 4.5 | 4 | 0.88 |

2 | 6.5 | 1 | 3.63 | 2.88 | 2.38 | 3.31 | Specified by purchaser | 12 | 5 | 8 | 0.75 |

2 1/2 | 7.5 | 1.13 | 4.13 | 3.13 | 2.88 | 3.94 | Specified by purchaser | 18 | 5.88 | 8 | 0.88 |

3 | 8.25 | 1.25 | 5 | 3.25 | 3.5 | 4.63 | Specified by purchaser | 23 | 6.63 | 8 | 0.88 |

3 1/2 | 9 | 1.38 | 5.5 | 3.38 | 4 | 5.25 | Specified by purchaser | 26 | 7.25 | 8 | 1 |

4 | 10.75 | 1.5 | 6.19 | 4 | 4.5 | 6 | Specified by purchaser | 42 | 8.5 | 8 | 1 |

5 | 13 | 1.75 | 7.31 | 4.5 | 5.56 | 7.44 | Specified by purchaser | 68 | 10.5 | 8 | 1.13 |

6 | 14 | 1.88 | 8.5 | 4.63 | 6.63 | 8.75 | Specified by purchaser | 81 | 11.5 | 12 | 1.13 |

8 | 16.5 | 2.19 | 10.63 | 5.25 | 8.63 | 10.75 | Specified by purchaser | 120 | 13.75 | 12 | 1.25 |

10 | 20 | 2.5 | 12.75 | 6 | 10.75 | 13.5 | Specified by purchaser | 190 | 17 | 16 | 1.38 |

12 | 22 | 2.63 | 15 | 6.13 | 12.75 | 15.75 | Specified by purchaser | 225 | 19.25 | 20 | 1.38 |

14 | 23.75 | 2.75 | 16.25 | 6.5 | 14 | 17 | Specified by purchaser | 280 | 20.75 | 20 | 1.5 |

16 | 27 | 3 | 18.5 | 7 | 16 | 19.5 | Specified by purchaser | 390 | 23.75 | 20 | 1.63 |

18 | 29.25 | 3.25 | 21 | 7.25 | 18 | 21.5 | Specified by purchaser | 475 | 25.75 | 20 | 1.75 |

20 | 32 | 3.5 | 23 | 7.5 | 20 | 24 | Specified by purchaser | 590 | 28.5 | 24 | 1.75 |

22 | 34.25 | 3.75 | 25.25 | 7.75 | 22 | 26.25 | Specified by purchaser | 720 | 30.63 | 24 | 1.88 |

24 | 37 | 4 | 27.25 | 8 | 24 | 28.25 | Specified by purchaser | 830 | 33 | 24 | 2 |

NOTE:

1. Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

6. Welding Neck Flange Bore Size SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100, SCH 120, SCH140, SCH160, XS

Inquiry