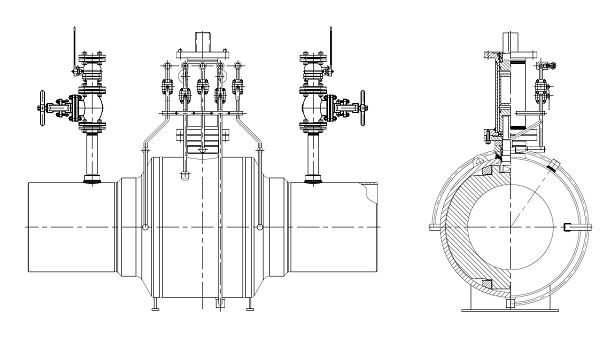

Product Details

Product Usage

Fully welded ball valves are widely used in various fields. Their superior quality and high performance stability are not achieved by ordinary cast steel ball valves. The service life of all-welded ball valves is far greater than cast steel ball valves. All-welded ball valves are widely used. City gas, urban heating, petrochemical, shipbuilding, steel, pressure regulating stations, power plants and other types of pipeline equipment.

Specification

Nominal diameter: DN150-DN1000

Pressure rating: PN16-PN64

Applicable temperature: -29 ° C -200 ° C

Use medium: water, gas, oil

Mode of operation: handle, gear, electric, pneumatic

Performance

1. The processing precision of the sphere is very precise, the operation is light and there is no bad interference.

2. Compared with the same kind of products in the same industry, the valve body is small and the appearance is beautiful.

3, using advanced raw materials, can protect the pressure above PN25.

4. The length of the valve body and the height of the valve stem can be adjusted according to the construction and design requirements of the pipeline.

5. The construction time and construction safety requirements are very high when constructing and maintaining the gas supply pipeline and the heating supply pipeline.

6. This valve adopts all-welded ball valve, which can be directly attached to the underground. The use of the latest engineering methods can minimize the space occupied by valve control and greatly save construction costs and engineering time. Moreover, it can prevent the danger of gas explosion, and the all-welded ball valve is a very safe valve.

Material

| No | Name | Material |

| 1 | Bonnet | ASTM A105 |

| 2 | Valve body | ASTM A105 |

| 3 | Sphere | ASTM A105+ENP |

| 4 | Anti-static spring | Assembly |

| 5 | Thrust bearing | PTFE |

| 6 | Sliding bearing | 304+PTFE |

| 7 | Lower stem | ASTM A105 |

| 8 | Bottom cover | ASTM A105 |

| 9 | Drain valve | ASTM A105+ENP |

| 10 | O-ring | VITON |

| 11 | Fireproof mat | SS304+ graphite |

| 12 | Socket head cap screws | ASTM A193 B7 |

| 13 | Foot frame | A3 |

| 14 | Seat | PPL |

| 15 | Seat fire pad | SS304+ graphite |

| 16 | Spring support | ASTM A105 |

| 17 | Spring | 17-7PH |

| 18 | O-ring | VITON |

| 19 | Seat support ring | ASTM A105+ENP |

| 20 | Sliding bearing | 304 |

| 21 | Thrust bearing | PTFE |

| 22 | Sliding bearing | 304+PTFE |

| 23 | Upper support | ASTM A105 |

| 24 | O-ring | VITON |

| 25 | O-ring | VITON |

| 26 | Y-ring seal | VITON |

| 27 | Fireproof mat | SS304+ graphite |

| 28 | Filler | Graphite |

| 29 | Socket head cap screws | ASTM A193 B7 |

| 30 | Socket head cap screws | ASTM A193 B7 |

| 31 | Valve stem | ASTM A182 F6a |

| 32 | Cylindrical pin | 35 |

| 33 | Stud | ASTM A193 B7 |

| 34 | Nut | ASTM A194 2H |

| 35 | Spring washer | 65Mn |

| 36 | Land | ASTM A105 |

| 37 | Flat key | 45 |

| 38 | Turbine | ASTM A105-HZn |

| 39 | Vent valve | ASTM A105-HZn |

Reliable seat seal

The all-welded natural gas ball valve uses a floating seat structure that allows the seat to float freely along the central axis of the valve. The valve is bi-directionally sealed and the initial seal is obtained by spring loading behind the seat under low pressure conditions. As the line pressure increases, the spring force behind the seat ring is supplemented, so that the valve seat and the ball remain in close contact, achieving a reliable sealing effect. The seat seal adopts a combined sealing structure. The primary seal can effectively prevent the solid particles from damaging the sealing surface. The secondary seal is a rubber ring seal, which can ensure the valve meets the “zero” leakage sealing requirement. Depending on the operating conditions, the valve seat can also be embedded with a polymer engineering plastic seal.

Low operating torque

The metal bushing with self-lubricating backing PTFE has a low friction torque, ensuring that the valve operates with low torque. Double truncation and excretion function (DBB)

The valve is in the closed position and the sides of the ball are simultaneously pressurized, and the medium (gas or liquid) in the chamber of the valve body can be vented from the drain valve (API 6D section 10).

Double piston effect seat design

The valve seat structure is designed such that both sides of the valve seat can be sealed under the action of pressure (double piston effect), and the double-sided sealed valve seat design features: once the upstream valve seat is damaged and leaks, the medium pressure enters the valve cavity to act on On the downstream side, the valve seat is pushed into close contact with the ball, so that the downstream valve seat can be sealed as it is.

Connection Size

Q61F/Q361F-Q41F/Q341F PN16/PN25/PN40

DN | L(RF) | L(WE) | D1 | D2 | H1 | H1 | W | W |

15 | 150 | 210 | 27 | 48 | 64 | - | 129 | - |

20 | 160 | 230 | 34 | 60 | 76 | - | 159 | - |

25 | 180 | 230 | 42 | 76 | 85 | - | 159 | - |

32 | 200 | 260 | 48 | 89 | 95 | - | 245 | - |

40 | 230 | 300 | 60 | 89 | 124 | - | 245 | - |

50 | 270 | 300 | 76 | 114 | 162 | - | 30 | - |

65 | 280 | 300 | 89 | 140 | 175 | - | 320 | - |

80 | 300 | 325 | 114 | 168 | 192 | 169 | 450 | - |

100 | 350 | 325 | 141 | 203 | 205 | 183 | 450 | 230 |

125 | 350 | 350 | 168 | 219 | 225 | 203 | 450 | 230 |

150 | 400 | 400 | 219 | 273 | 245 | 224 | 1000 | 230 |

200 | 502 | 521 | 273 | 351 | 285 | 262 | 1000 | 320 |

250 | 568 | 560 | 325 | 426 | 348 | 322 | 1500 | 350 |

300 | 648 | 635 | 377 | 508 | 355 | 350 |

Hot Tags: fully welded natural gas ball valve, China, manufacturers, suppliers, factory, cheap, customized

Previous: Turbine Fully Welded Ball Valve

Inquiry