Product Details

Product Description

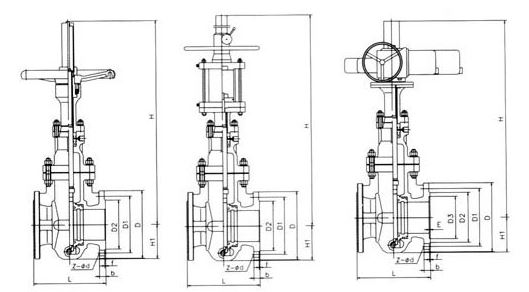

The cast steel B.B flanged slab gate valve is a sliding valve with a closing member that is a parallel gate. The closing member may be a single shutter or a double shutter with a distracting mechanism therebetween. The pressing force of the shutter to the valve seat is controlled by the medium pressure acting on the floating shutter or the floating valve seat. In the case of a double gate slab gate valve, the expansion mechanism between the two shutters can supplement this pressing force.

Structural Features

The cast steel B.B flanged gate valve adopts a new floating seal structure, which is suitable for oil, natural gas and other pipelines with a pressure of not more than 15.0 MPa and a temperature of -29 to 121 ° C. It is used as a control medium for opening and closing and adjusting devices. The structure design is novel, the material selection is appropriate, the test is strict, the operation is light, and it has strong anti-corrosion, wear-resistance and erosion-resistance performance. It is an ideal new equipment in the petroleum industry.

1. It adopts floating valve seat, two-way opening and closing, reliable sealing and flexible opening and closing.

2. The gates are provided with guide strips for precise guiding, while the sealing surfaces are spray-welded with hard alloy and resistant to erosion.

3. The valve body has high bearing capacity, and the channel is straight-through. When fully open, it is similar to the straight pipe of the ram and the flow tube is small. The valve stem adopts composite packing and multiple sealing, which makes the sealing reliable and the friction is small.

4. When closing the valve, turn the handwheel clockwise and move the ram down to the bottom. Due to the pressure of the medium, push the inlet end seal seat toward the ram direction to form a larger sealing pressure, thus forming the first seal. . At the same time, the shutter is pressed against the outlet end seal seat to form a double seal.

5. Due to the double seal, the consumables can be replaced without affecting the work of the pipeline.

6. When the gate is opened, turn the handwheel counterclockwise, move the gate, and the guide hole will penetrate with the passage hole. As the gate rises, the through hole gradually increases. When the limit position is reached, the flow guiding hole and the channel hole coincide with each other, and are fully opened at this time.

Design Standard

Design and manufacturing standards: JB/T 5298

Structure length standard: JB/T 5298

Connection flange standard: GB/T 9113

Pressure temperature grade: GB/T 12224-2005

Test and inspection standards: GB/T 13927-2008, JB/T 5298

| Part Name | Component material | |||

| JB/T77298 | API 6D | |||

| Valve/bonnet | WCB | WCB | A352-LCB | A351-CF8N |

| Gate | 2Cr13+ENP | 20CrMoV+STL | ANSI 410+ENP | ANSI 316+ENP |

| Valve stem | 2Cr13 | 2Cr13 | A182-F6a | A182-F316S |

| Seat | 25+PTFE | 20CrMoV+STL | A105+PTFE | A182-F316+PTFE |

| Filler | NBR/FPM | Flexible graphite | PTFE | |

| Gasket | 18-8/flexible graphite | |||

| Bolt | 35 | 35CrMo | A193-B7M | A193-B8 |

| proper temperature | -29~250℃ | -29~550°C | -46~250℃ | -40~200℃ |

| Applicable medium | Water, oil | Steam, oil | Propane, ethylene | Nitric acid |

| Nominal diameter | Main dimensions and connection dimensions | ||||||

L | D | D1 | D2 | Z-Φd | H | D0 | |

Z43PF-16C | |||||||

100 | 150 | 215 | 180 | 155 | 8-Φ18 | 700 | 300 |

125 | 150 | 245 | 210 | 185 | 8-Φ18 | 798 | 350 |

150 | 150 | 280 | 240 | 210 | 8-Φ23 | 895 | 350 |

200 | 180 | 335 | 295 | 265 | 12-Φ23 | 1130 | 350 |

250 | 180 | 405 | 355 | 320 | 12-Φ25 | 1290 | 400 |

300 | 200 | 460 | 410 | 375 | 12-Φ25 | 1480 | 450 |

350 | 200 | 520 | 470 | 435 | 16-Φ25 | 1660 | 450 |

400 | 218 | 580 | 525 | 485 | 16-Φ30 | 1850 | 500 |

450 | 218 | 640 | 585 | 545 | 20-30 | 2080 | 500 |

500 | 229 | 705 | 650 | 608 | 20-34 | 2300 | 600 |

600 | 248 | 840 | 770 | 718 | 20-41 | 2680 | 800 |

700 | 286 | 910 | 840 | 788 | 24-41 | 3080 | 800 |

800 | 286 | 1020 | 950 | 898 | 24-41 | 3491 | 1000 |

Z43PF-25 | |||||||

100 | 150 | 230 | 190 | 160 | 8-Φ23 | 700 | 300 |

125 | 150 | 270 | 220 | 188 | 8-Φ25 | 798 | 350 |

150 | 150 | 300 | 250 | 218 | 8-Φ25 | 895 | 350 |

200 | 180 | 360 | 310 | 278 | 12-Φ25 | 1130 | 350 |

250 | 180 | 425 | 370 | 332 | 12-Φ30 | 1290 | 400 |

300 | 200 | 485 | 430 | 390 | 16-Φ30 | 1480 | 450 |

350 | 200 | 550 | 490 | 448 | 16-Φ34 | 1660 | 450 |

400 | 218 | 610 | 550 | 505 | 16-Φ34 | 1850 | 500 |

450 | 218 | 660 | 600 | 555 | 20-Φ34 | 2080 | 500 |

500 | 229 | 730 | 660 | 610 | 20-Φ41 | 2300 | 600 |

600 | 248 | 840 | 770 | 718 | 20-Φ41 | 2680 | 800 |

700 | 286 | 955 | 875 | 815 | 24-Φ48 | 3080 | 800 |

800 | 286 | 1070 | 990 | 930 | 24-Φ48 | 3491 | 1000 |

Hot Tags: cast steel b.b flanged slab gate valve, China, manufacturers, suppliers, factory, cheap, customized

Previous: Electric Flange Slab Gate Valve

Inquiry