Product Details

Product Description

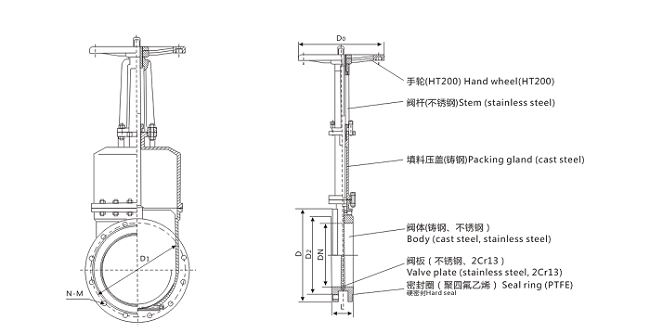

The opening and closing member of the manual knife gate valve is a shutter. The direction of movement of the shutter is perpendicular to the direction of the fluid. The blade is cut by a blade-shaped shutter that can cut the fiber material. The valve body does not actually have a chamber, and the gate is guided at the side. The groove is lifted and lowered, and the lug at the bottom is pressed against the valve seat. If a high medium sealing property is required, an O-shaped sealing seat can be used for the two-way sealing.

Feature

1. Lifting ram sealing surface can scrape the adhesive on the sealing surface and automatically remove debris.

2. Stainless steel rams prevent seal leakage caused by corrosion.

3. The hard all-gold sealing surface can guarantee the sealing wear resistance and requirements.

4. There is no groove on the sealing surface of the valve body, and no accumulation is generated, which can ensure flexible opening.

5. Short structure length, can save raw materials, installation space and effectively support pipeline strength.

6. The scientific upper sealing stuffing box design makes the upper sealing safe and effective and durable.

7. The triangular bracket saves raw materials and guarantees the required mechanical properties.

8. The guide block on the valve body makes the gate move correctly, and the four extrusion blocks ensure the effective sealing of the gate.

9. The valve body rib design improves the strength of the valve body.

10. Stainless steel stem is durable, the studs make the opening and closing more rapid.

11. The drive mechanism can be arbitrarily selected.

12. 150 or more caliber, fully enclosed structure, more effective to open and prevent leakage.

13. The sealing surface of the fluororubber can achieve the sealing effect and increase the operating temperature.

14. The rubber sealing surface is directly vulcanized in the valve body and will not fall off.

Application

1. Mining, washing coal, steel industry - used for washing coal pipelines, filter slurry pipelines, etc., ash discharge pipelines;

2. Purification device - for wastewater, mud, dirt and clarified water with suspended solids;

3. Paper industry - for any concentration of pulp, water mixture;

4. Power plant ash removal - for ash slurry

Nominal diameter | Main dimensions and connection dimensions | |||||||

L | D | D1 | D2 | b | Z-d | H | D0 | |

| PZ73X/H-10C | ||||||||

50 | 50 | 160 | 125 | 100 | 16-3 | 4-Φ18 | 285 | 180 |

65 | 50 | 180 | 145 | 120 | 18-3 | 4-Φ18 | 298 | 180 |

80 | 50 | 195 | 160 | 135 | 20-3 | 8-Φ18 | 315 | 220 |

100 | 50 | 215 | 180 | 155 | 20-3 | 8-Φ18 | 365 | 220 |

125 | 50 | 245 | 210 | 185 | 22-3 | 8-Φ18 | 400 | 230 |

150 | 60 | 280 | 240 | 210 | 24-3 | 8-Φ23 | 475 | 280 |

200 | 60 | 335 | 295 | 265 | 26-3 | 12-Φ23 | 540 | 360 |

250 | 70 | 405 | 355 | 320 | 30-3 | 12-Φ25 | 630 | 360 |

300 | 80 | 460 | 410 | 375 | 30-3 | 12-Φ25 | 780 | 400 |

350 | 90 | 520 | 470 | 435 | 34-4 | 16-Φ25 | 885 | 400 |

400 | 100 | 580 | 525 | 485 | 36-4 | 16-Φ30 | 990 | 400 |

450 | 120 | 640 | 585 | 545 | 40-4 | 20-Φ30 | 1100 | 530 |

500 | 130 | 705 | 650 | 608 | 44-4 | 20-Φ34 | 1200 | 530 |

600 | 140 | 840 | 770 | 718 | 48-5 | 20-Φ36 | 1450 | 600 |

700 | 165 | 910 | 840 | 788 | 50-5 | 24-Φ41 | 1700 | 600 |

800 | 190 | 1020 | 950 | 898 | 52-5 | 24-Φ41 | 2000 | 680 |

900 | 203 | 1120 | 1050 | 998 | 54-5 | 28-Φ41 | 2300 | 680 |

PZ73X/H-16C | ||||||||

50 | 50 | 160 | 125 | 100 | 20-3 | 4-Φ18 | 285 | 180 |

65 | 50 | 180 | 145 | 120 | 22-3 | 8-Φ18 | 298 | 180 |

80 | 50 | 195 | 160 | 135 | 22-3 | 8-Φ18 | 315 | 220 |

100 | 50 | 230 | 190 | 160 | 24-3 | 8-Φ23 | 365 | 220 |

125 | 50 | 270 | 220 | 188 | 28-3 | 8-Φ25 | 400 | 230 |

150 | 60 | 300 | 250 | 218 | 30-3 | 8-Φ25 | 475 | 280 |

200 | 60 | 360 | 310 | 278 | 34-3 | 12-Φ25 | 540 | 360 |

250 | 70 | 425 | 370 | 332 | 36-3 | 12-Φ30 | 630 | 360 |

300 | 80 | 485 | 430 | 390 | 40-4 | 16-Φ30 | 780 | 400 |

350 | 90 | 550 | 490 | 448 | 44-4 | 16-Φ34 | 885 | 400 |

400 | 100 | 610 | 550 | 505 | 48-4 | 16-Φ34 | 990 | 400 |

450 | 120 | 640 | 585 | 545 | 40-4 | 20-Φ30 | 1100 | 530 |

500 | 130 | 705 | 650 | 608 | 44-4 | 20-Φ34 | 1200 | 530 |

600 | 140 | 840 | 770 | 718 | 48-5 | 20-Φ36 | 1450 | 600 |

700 | 165 | 910 | 840 | 788 | 50-5 | 24-Φ41 | 1700 | 600 |

800 | 190 | 1020 | 950 | 898 | 52-5 | 24-Φ41 | 2000 | 680 |

900 | 203 | 1120 | 1050 | 998 | 54-5 | 28-Φ41 | 2300 | 680 |

Hot Tags: manual knife gate valve, China, manufacturers, suppliers, factory, cheap, customized

Inquiry