Product Details

Product Usage:

Q361F type PN1.6-PN2.5 carbon steel fully welded ball valve is widely used in various fields. Its superior quality and high performance stability are not achieved by ordinary cast steel ball valves. The service life of all welded ball valves is far greater than Cast steel ball valves, all welded ball valves are widely used in urban gas, urban heating, petrochemical, shipbuilding, steel, pressure regulating stations, power plants and other pipeline equipment.

Advantage

1. The fluid resistance of the carbon steel fully welded ball valve is small, and its resistance coefficient is equal to the pipe length of the same length.

2. The structure is simple, small in size and light in weight.

3. It is close and reliable. At present, the sealing surface material of the ball valve is widely used in plastic and has good sealing performance. It has also been widely used in vacuum systems.

4. The operation is convenient, the opening and closing is rapid, and the rotation is 90° from full opening to full closing, which is convenient for long-distance control.

5. The maintenance is convenient, the ball valve has a simple structure, and the sealing ring is generally movable, and the disassembly and replacement are relatively convenient.

6. When the carbon steel fully welded ball valve is fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium, and the medium does not cause erosion of the sealing surface of the valve.

Material

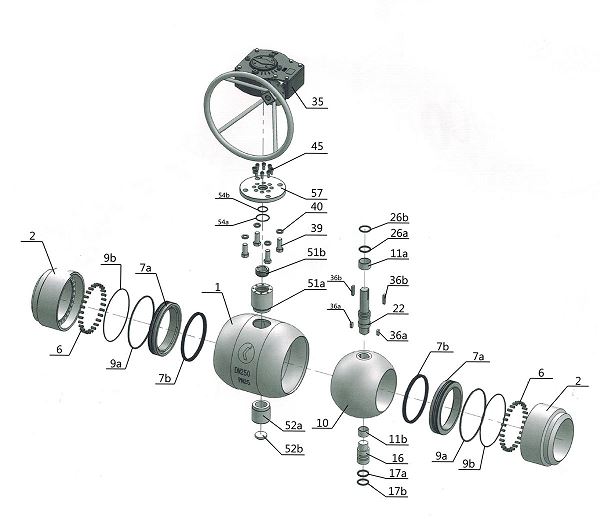

| No | Name | Material |

| 1 | Bonnet | ASTM A105 |

| 2 | Valve body | ASTM A105 |

| 3 | Sphere | ASTM A105+ENP |

| 4 | Anti-static spring | Assembly |

| 5 | Thrust bearing | PTFE |

| 6 | Sliding bearing | 304+PTFE |

| 7 | Lower stem | ASTM A105 |

| 8 | Bottom cover | ASTM A105 |

| 9 | Drain valve | ASTM A105+ENP |

| 10 | O-ring | VITON |

| 11 | Fireproof mat | SS304+ graphite |

| 12 | Socket head cap screws | ASTM A193 B7 |

| 13 | Foot frame | A3 |

| 14 | Seat | PPL |

| 15 | Seat fire pad | SS304+ graphite |

| 16 | Spring support | ASTM A105 |

| 17 | Spring | 17-7PH |

| 18 | O-ring | VITON |

| 19 | Seat support ring | ASTM A105+ENP |

| 20 | Sliding bearing | 304 |

| 21 | Thrust bearing | PTFE |

| 22 | Sliding bearing | 304+PTFE |

| 23 | Upper support | ASTM A105 |

| 24 | O-ring | VITON |

| 25 | O-ring | VITON |

| 26 | Y-ring seal | VITON |

| 27 | Fireproof mat | SS304+ graphite |

| 28 | Filler | Graphite |

| 29 | Socket head cap screws | ASTM A193 B7 |

| 30 | Socket head cap screws | ASTM A193 B7 |

| 31 | Valve stem | ASTM A182 F6a |

| 32 | Cylindrical pin | 35 |

| 33 | Stud | ASTM A193 B7 |

| 34 | Nut | ASTM A194 2H |

| 35 | Spring washer | 65Mn |

| 36 | Land | ASTM A105 |

| 37 | Flat key | 45 |

| 38 | Turbine | ASTM A105-HZn |

| 39 | Vent valve | ASTM A105-HZn |

Connection Size

Q61F/Q361F-Q41F/Q341F PN16/PN25/PN40

DN | L(RF) | L(WE) | D1 | D2 | H1 | H1 | W | W |

15 | 150 | 210 | 27 | 48 | 64 | - | 129 | - |

20 | 160 | 230 | 34 | 60 | 76 | - | 159 | - |

25 | 180 | 230 | 42 | 76 | 85 | - | 159 | - |

32 | 200 | 260 | 48 | 89 | 95 | - | 245 | - |

40 | 230 | 300 | 60 | 89 | 124 | - | 245 | - |

50 | 270 | 300 | 76 | 114 | 162 | - | 30 | - |

65 | 280 | 300 | 89 | 140 | 175 | - | 320 | - |

80 | 300 | 325 | 114 | 168 | 192 | 169 | 450 | - |

100 | 350 | 325 | 141 | 203 | 205 | 183 | 450 | 230 |

125 | 350 | 350 | 168 | 219 | 225 | 203 | 450 | 230 |

150 | 400 | 400 | 219 | 273 | 245 | 224 | 1000 | 230 |

200 | 502 | 521 | 273 | 351 | 285 | 262 | 1000 | 320 |

250 | 568 | 560 | 325 | 426 | 348 | 322 | 1500 | 350 |

300 | 648 | 635 | 377 | 508 | 355 | 350 |

The main welding ball valve Q361F main selection principle:

1. Valve stem anti-flying structure

2. Anti-static device

3. Fireproof structure

4. The central flange has no external leakage structure

5. Automatic pressure relief structure

Hot Tags: carbon steel fully welded ball valve, China, manufacturers, suppliers, factory, cheap, customized

Previous: No Information

Inquiry