Product Details

Product Specification

|

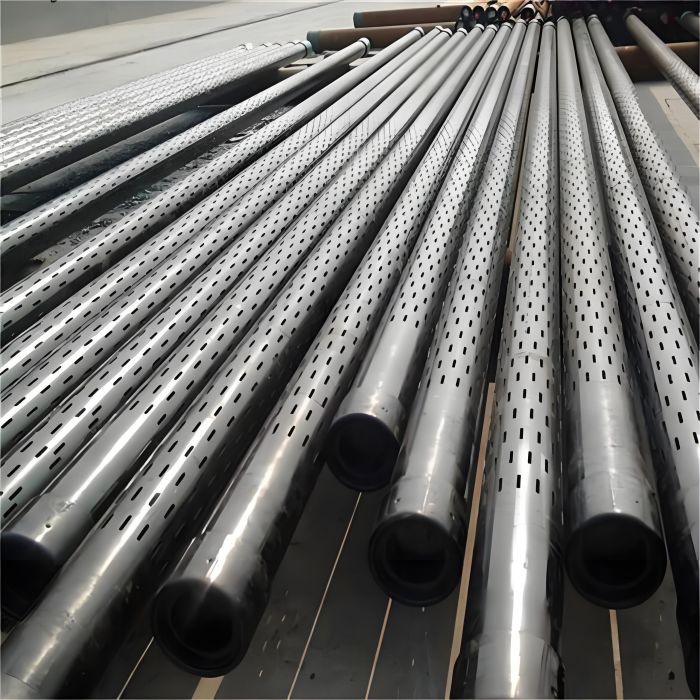

Material |

Stainless steel 304 and 316L, Carbon steel |

|

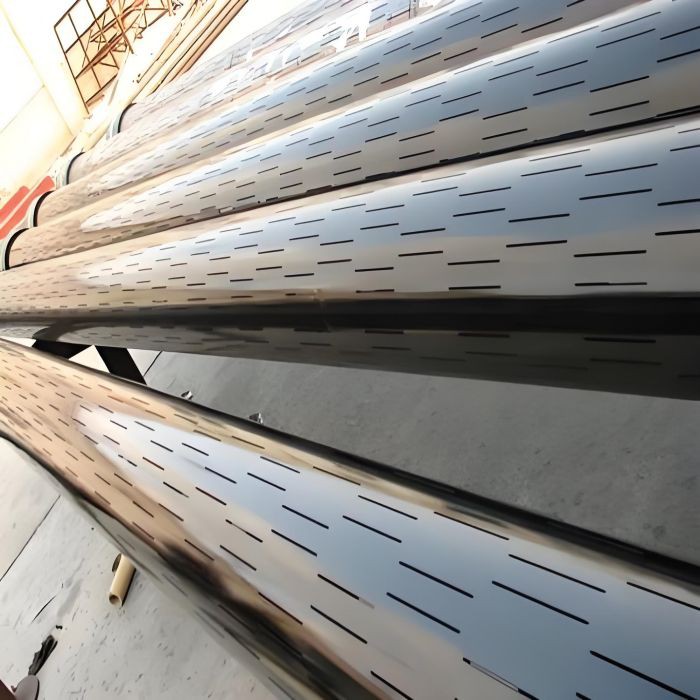

Slot size |

0.02mm~15mm |

|

Length |

Customized |

|

Size |

Customized |

|

Wire shape |

V shape, wedge wire |

|

End Finishing |

Thread fitting, Flange, Closed Plated, Metal Ring, etc. |

Product Detail

|

Standard |

DIN; GB; ISO; JIS; BA; ANSI |

|

End connection |

Welding, Thread and Flange |

|

Surface treatment |

Galvanized, Painted, Polish, Packiled and Passivation, etc. |

|

Packing |

SCREENS WITH TUBE CAPS, PLASTIC BUBBLE WRAP, OUTSIDE WOOD STRIP OR WOOD CASE PROTECTION. |

Feature

1. Greater Efficiency: A well screen for vertical well is designed to maximize the flow of water into the well while minimizing the amount of sand and other solid particles that can clog the well. This type of screen is highly efficient, providing maximum flow rates with minimal maintenance.

2. Durability: Water well screens for vertical wells are made from durable materials such as stainless steel, which provides excellent resistance to corrosion and erosion. This means that these screens can last for many years, even in harsh environments.

3. Cost-Effective: Vertical well screens are cost-effective, especially over the long run. Their durability means that they do not need to be replaced as frequently as other types of screens, which can lead to significant cost savings over time.

4. Versatility: Water well screens for vertical wells can be used in a wide range of well diameters. This versatility means that they can be used in a variety of applications, from small domestic wells to larger agricultural and industrial water wells.

5. Improved Water Quality: The unique design of water well screens for vertical wells ensures that the water extracted from the well is of the highest quality. The screen blocks debris such as sand and silt, ensuring that the water is clean and free from contaminants.

Water well screens for vertical wells have unique features that make them the optimal choice for water well installations. These screens are highly efficient and durable while also being cost-effective. Additionally, they can provide excellent water quality, making them a top choice for many industries that rely on underground water sources. Ultimately, choosing the right water well screen for a vertical well is an important decision that should be made with careful consideration to ensure the highest quality water for generations to come.

Application

1.Excavation function: In coal, mining and other industries, the water well screens for vertical wells can be used to excavate and separate ore or coal of different sizes for subsequent processing and processing.

2.Filtration: In chemical, pharmaceutical, and food industries, water well screens for vertical wells can be used to filter and separate impurities in mixtures to ensure the quality and purity of products.

3.Classification function: In oil wells and other industries, water well screens for vertical wells can be used to classify and filter crude oil with high sand content to reduce the wear and tear of equipment and improve oil production efficiency.

4.Anti-clogging effect: In industries such as water treatment and pollution control, water well screens for vertical wells can be used to prevent equipment pipelines from being blocked.

Hot Tags: water well screen for vertical well, China, manufacturers, suppliers, factory, cheap, customized

Inquiry