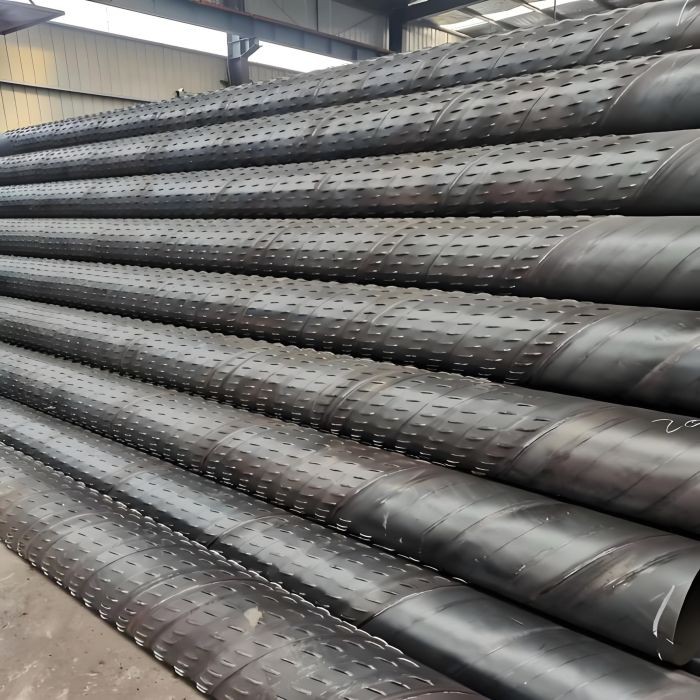

Product Details

Product Specification

|

Material |

Stainless steel 304 and 316L, Carbon steel |

|

Slot size |

0.02mm~15mm |

|

Length |

Customized |

|

Size |

Customized |

|

Wire shape |

V shape, wedge wire |

|

End Finishing |

Thread fitting, Flange, Closed Plated, Metal Ring, etc. |

Product Detail

|

Standard |

DIN; GB; ISO; JIS; BA; ANSI |

|

End connection |

Welding, Thread and Flange |

|

Surface treatment |

Galvanized, Painted, Polish, Packiled and Passivation, etc. |

|

Packing |

SCREENS WITH TUBE CAPS, PLASTIC BUBBLE WRAP, OUTSIDE WOOD STRIP OR WOOD CASE PROTECTION. |

Feature

Long life bridge-slot water well screens are designed with durability in mind. By optimizing the structural design and selecting high-strength materials, the screen tube is able to withstand the harsh groundwater environment and long-term water erosion. Its sturdy and durable construction enables the screen to maintain long-term stable operation even under harsh working conditions, effectively extending the service life.

The design of the bridge-slot structure makes the long life bridge-slot water well screens have a larger filtration area and higher filtration efficiency. As the water flows through the bridge trough, it passes through a multi-layered filtration layer to effectively remove impurities and particulate matter from the water. At the same time, the bridge-groove structure can also reduce the erosion of the screen by the water flow, reduce the wear of the screen, and thus extend the service life.

Long life bridge-slot water well screens are made of high-quality materials, such as corrosion-resistant, high-strength alloy steel. These materials have excellent corrosion resistance, mechanical properties, and fatigue resistance, and are able to remain stable under long-term water washout and groundwater corrosion. The choice of high-quality materials allows the screen to have a longer service life and better durability.

The long life bridge-slot water well screen adopts advanced manufacturing processes, such as precision welding, heat treatment, etc. These processes ensure that the screen is securely connected, tightly sealed, and resistant to external pressure and groundwater erosion. The advanced manufacturing process also improves the overall performance and stability of the screen, further extending the service life.

Application

1.Excavation function: In coal, mining and other industries, the long life bridge-slot water well screen can be used to excavate and separate ore or coal of different sizes for subsequent processing and processing.

2.Filtration: In chemical, pharmaceutical, and food industries, sieve tubes can be used to filter and separate impurities in mixtures to ensure the quality and purity of products.

3.Classification function: In oil wells and other industries, long life bridge-slot water well screen can be used to classify and filter crude oil with high sand content to reduce the wear and tear of equipment and improve oil production efficiency.

4.Anti-clogging effect: In industries such as water treatment and pollution control, long life bridge-slot water well screen can be used to prevent equipment pipelines from being blocked.

Hot Tags: long life bridge-slot water well screen, China, manufacturers, suppliers, factory, cheap, customized

Inquiry