Product Details

Product Specification

|

Material |

Stainless steel 304 and 316L, Carbon steel |

|

Slot size |

0.02mm~15mm |

|

Length |

Customized |

|

Size |

Customized |

|

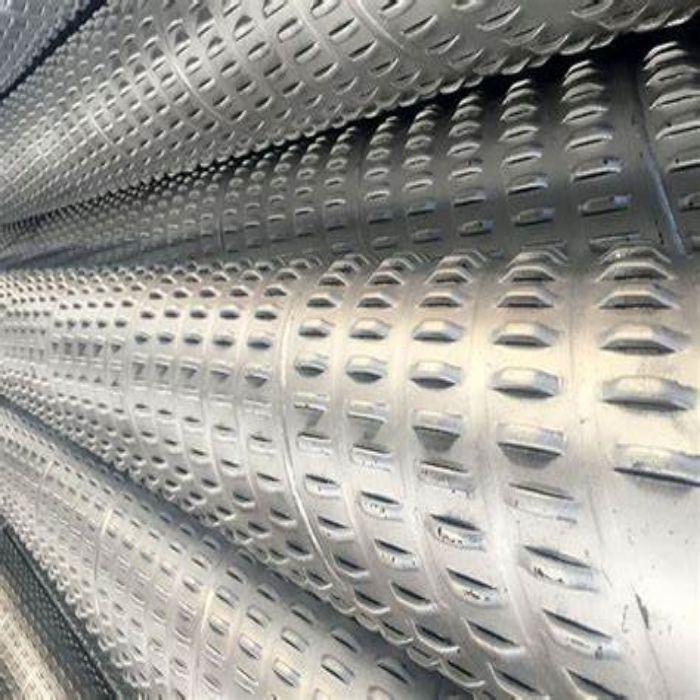

Wire shape |

V shape, wedge wire |

|

End Finishing |

Thread fitting, Flange, Closed Plated, Metal Ring, etc. |

Product Detail

|

Standard |

DIN; GB; ISO; JIS; BA; ANSI |

|

End connection |

Welding, Thread and Flange |

|

Surface treatment |

Galvanized, Painted, Polish, Packiled and Passivation, etc. |

|

Packing |

SCREENS WITH TUBE CAPS, PLASTIC BUBBLE WRAP, OUTSIDE WOOD STRIP OR WOOD CASE PROTECTION. |

Feature

One of the key advantages of bridge-slot water well screens for water intake system is their high open area, which allows for maximum flow rates. They also have a larger diameter than traditional well screens, which increases the flow capacity of a given well or borehole. In addition, they have a longer lifespan than other types of screens, which translates into less downtime and maintenance costs over the long haul.

Bridge-slot water well screens for water intake system are also highly adaptable to a wide range of geological conditions. They are available in a variety of sizes, lengths, diameters, and slot widths to suit different requirements and geological formations. They can be customized to fit a specific water intake system, which ensures optimal performance and efficiency.

Application

Water Filtration:

Bridge-slot screens are designed to filter out sand, gravel, and other particles from the water as it enters the well. This prevents these particles from entering the water intake system and causing damage to pumps, valves, and other equipment.

Sand Control:

In areas with high levels of sand and sediment, bridge-slot screens provide effective sand control. They prevent the ingress of sand into the production tubing, which can lead to erosion, wear, and ultimately, failure of the water intake system.

Hot Tags: bridge-slot water well screen for water intake system, China, manufacturers, suppliers, factory, cheap, customized

Inquiry