Product Details

Product Specification

|

Material |

Stainless steel 304 and 316L, Carbon steel |

|

Slot size |

0.02mm~15mm |

|

Length |

Customized |

|

Size |

Customized |

|

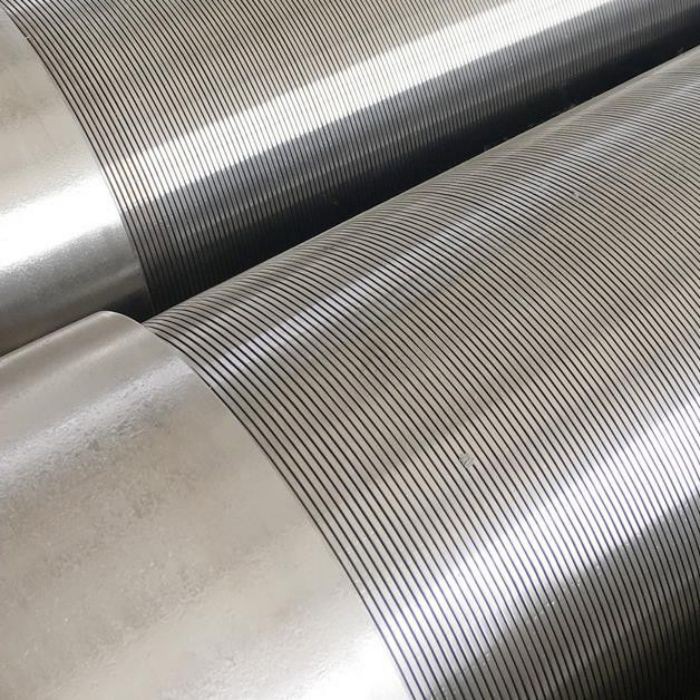

Wire shape |

V shape, wedge wire |

|

End Finishing |

Thread fitting, Flange, Closed Plated, Metal Ring, etc. |

Product Detail

|

Standard |

DIN; GB; ISO; JIS; BA; ANSI |

|

End connection |

Welding, Thread and Flange |

|

Surface treatment |

Galvanized, Painted, Polish, Packiled and Passivation, etc. |

|

Packing |

SCREENS WITH TUBE CAPS, PLASTIC BUBBLE WRAP, OUTSIDE WOOD STRIP OR WOOD CASE PROTECTION. |

Feature

The anti-blocking multilayer oil well screen comprises several layers of filtering elements, each with a different pore size. The larger pores catch the bigger particles, while the smaller pores remove the finer ones. This design avoids the accumulation of debris on the screen and allows for higher flow rates. Moreover, the multilayer structure enhances the durability of the screen, as it can withstand pressure variations and chemical attacks better than single-layer screens.

The core of the anti-blocking multilayer oil well screen lies in the design of the filtering layers and the materials used for its production. The different layers are meticulously crafted to achieve the optimal balance between filtration efficiency and flow rate, while the materials are selected based on their compatibility with the fluid and the downhole conditions. For example, stainless steel alloys are often used for their resistance to corrosion and erosion, while sintered metal powders provide a high degree of porosity and strength.

The advantages of the anti-blocking multilayer oil well screen are numerous. First, it increases the productivity of the well, thanks to its higher flow rates and reduced clogging. This translates into higher profits for the oil and gas companies and a more efficient use of natural resources. Second, it reduces the maintenance costs, as the screen lasts longer and requires fewer interventions. Third, it improves the safety and environmental sustainability of the extraction process, by reducing the risk of wellbore collapse and avoiding spills and leaks.

Application

1. Oil industry: The screen has important applications in oil exploration and production and oil well enhanced recovery, and its role is mainly to filter crude oil with high sand content and ensure the normal operation of equipment.

2 Chemical industry: the chemical industry in the production process requires that impurities can not exceed a certain limit, the screen has an important role in filtering impurities, can be used to separate different sizes of particles and filter impurities in the mixture.

3. Other industries: Screens can also be used in water treatment, pollution control, and impurity removal, grading and crushing in various industrial processes.

Hot Tags: anti-blocking multilayer oil well screen, China, manufacturers, suppliers, factory, cheap, customized

Inquiry